Projects Overview B3/III Robust Design Optimization of hybrid reinforced strengthening layers at impact loading

B3/III Robust Design Optimization of hybrid reinforced strengthening layers at impact loading

Motivation

The first two cohorts of the RTG 2250 laid the fundamentals for the deterministic numerical modeling of textile as well as hybrid reinforced concrete on the mesoscopic level under consideration of averaged material responses from experimental investigations. However, the experimental results show considerable scattering. To obtain a realistic representation on structural level, aleatoric and epistemic uncertainties of the experimentally obtained material behavior should be considered in the numerical modeling, as well as in the computational homogenization approach.

State of Research and preliminary work

In context of the multi-scale modeling, the first and second cohort developed a Representative Volume Element for the mesoscopic structure of the reinforced concrete. Based on the numerical investigations on the load-bearing behavior of this unit cell, an efficient method for computational homogenization of the material’s constitutive response on the basis of artificial neural networks was developed and adapted for the application to inelastic behavior. The data necessary for this approach was obtained by deterministic numerical simulations of materials at the mesoscale which represent an approximation of the realistic material behavior. However, experimental investigations conducted in the first and second cohort showed scattering in the material behavior. Therefore, the uncertainty with respect to the material behavior should also be considered in the numerical modeling and in the subsequent computational homogenization approach.

Scientific Task and project goals

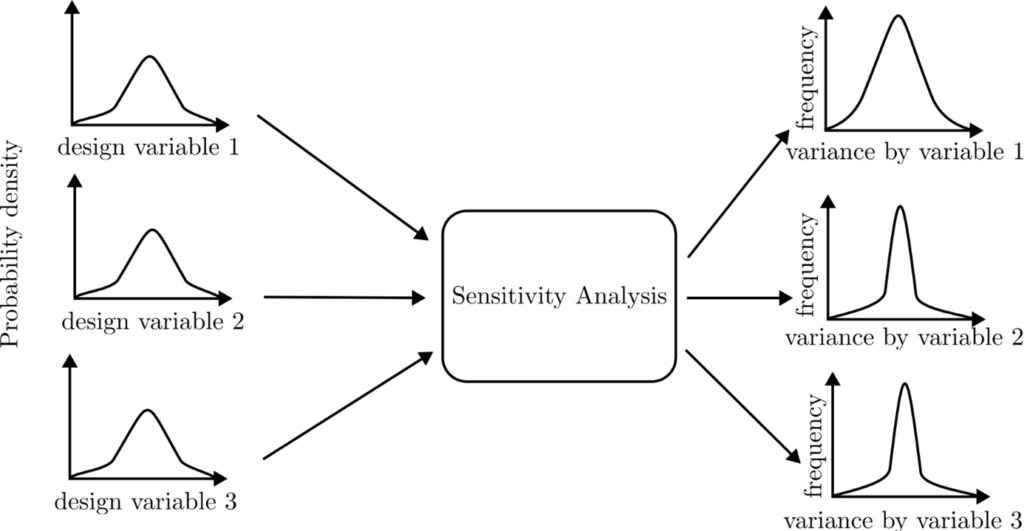

Within the scope of this project, the existing Representative Volume Element for textile and hybrid reinforced concrete should be investigated while considering the experimentally observed fluctuations in the material responses. Therefore, it is necessary to quantify the uncertainties of the composite properties originating from the mesoscopic material structure and manufacturing imperfections. These results will enable numerical multi-scale uncertainty quantification based on the meso-mechanical scale and meta models developed in B3/I and B3/II, as well as a sensitivity analysis of hybrid reinforced concrete (HRC) with regard to material and meso-structural parameters. The obtained models should be extended to impact loading and applied in numerical simulations on a structural scale. The plate and column elements defined as common benchmark examples throughout the RTG 2250 will be core of the structural investigations based on the input of the experimental subprojects. Moreover, these developments will allow for a Robust Design optimization of hybrid reinforced concrete with respect to impact loading.

Interaction with other projects of cohort III

For the investigations on the uncertainties of the composite properties, a cooperation with the experimental projects A2/III, A3/III and A4/III is desired, as a large amount of experimental data for different loading scenarios of the HRC is required. The performance of the resulting models should be validated by experimental investigations of the doctoral projects A4/III, A5/III and A6/III based on the common benchmark examples. Within the scope of Robust Design Optimization, project B3/III can provide information on possible improvements of the HRC structures. Furthermore, a collaboration with the doctoral project C3 for management and analysis of the data will be initiated.

Contributors

© Dominik Junger

Doctoral Researcher

ABHINAV ANIL KHEDKAR, M.SC

Institute of Structural Analysis

Technische Universität Dresden

Georg-Schumann-Straße 7

01187 Dresden

Germany

Principal Investigator

Univ.-Prof. Dr.-Ing. habil. Michael Kaliske

Institute of Construction Materials

Von-Mises-Bau (VMB), Room 101A Georg-Schumann-Straße 7

01187 Dresden

Germany

- michael.kaliske@tu-dresden.de

- Institute

- +49 351 463 34386

- +49 351 463 37086

in cooperation with

Prof. Dr.-Ing. Stefan Löhnert

Institute of Mechanics and Shell Structures

TU Dresden, Faculty of Civil Engineering, 3rd floor, room 03-017

August-Bebel-Straße 30

01219 Dresden

Germany

- stefan.loehnert@tu-dresden.de

- Institute

- +49 351 463 43231

- +49 351 463 43235

in cooperation with

Univ.-Prof. Dr.-Ing. habil. Dipl.-Wirt. Ing. Chokri Cherif

Institute of Textile Machinery and High

Performance Material Technology (ITM)

Hohe Straße 6, Room 138

01069 Dresden

Germany

- chokri.cherif@tu-dresden.de

- Institute

- +49 351 463 39300

- +49 351 463 39301