Projects Overview A2/III Polymer fibres with chemical functionalization based on sustainable material concepts

A2/III Polymer fibres with chemical functionalization based on sustainable material concepts

Motivation

To increase ductility and toughness in SHCC (Strain-hardening cement-based composites), polymer fibres are used whose tensile strength as well as fibre-matrix composite zone are the main contributors to the energy absorption of the composites. The findings from Phase I of the project were used in Phase II to develop and manufacture polypropylene (PP) bicomponent fibres with high surface roughness [SCH1-3]. Intensive mechanical anchoring of the fibres in the matrix resulted in a significant increase in energy absorption under dynamic loading. A targeted chemical functionalization of the newly developed fibres is still pending; it should further improve the wettability of the fibres and the fibre-matrix interaction.

State of research and own preliminary work

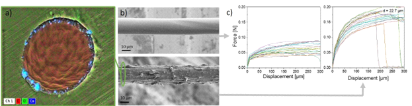

In the second cohort, new bicomponent fibres were developed which have a PP-core and an outer shell of PP with CaCO3-particles incorporated by compounding [SCH4-6]. The fundamental development work included, among other factors, investigations of the degree of stretching, the core-shell ratio, and defined particle contents with regard to maximum surface roughness. The preliminary tests, which were initially carried out in piston spinning trials, were successfully scaled up and produced on a kg-scale close to industrial conditions. The tests further showed that with increasing particle content (up to approx. 40 vol.%) the spinnability and the fibre tensile strength decrease, but at 10 vol.% fibre spinning is possible continuously. The use of appropriate particle contents with simultaneous increased chemical bonding can lead to a further improvement in spinning stability, fibre tensile strength and composite behaviour at impact.

PP-bicomponent fibres; a) EDX-image of the core-shell-structure in cross section showing the distribution of the CaCO3-particles; b) REM-images of conventional PP-fibres and new fibres with rough surface, c) Force-displacement curves of these fibres in the single fibre pull-out test

Scientific problem and project goals

In the third cohort, the fibre-matrix bonding will be further increased by the already successful mechanical anchoring of the PP fibres through chemical functionalization. The investigations will focus on a functionalization of the shell polymer itself or a surface functionalization by sizing. Compared to the previous micromechanical work, the focus will now be on the processability, distribution and wetting of the fibres during SHCC production and mechanical bond testing. Furthermore, the use of recycled polypropylene in the shell structure of the fibres will be tested.

Interaction with other Projects of Cohort III

In cooperation with A3, a sustainable LC3 matrix was already developed in the 2nd cohort, which is suitable for the production of a ductile, mineral composite with PP fibres. The cooperation will be intensified regarding the incorporation of the fibres into the matrix as well as mechanical tests before and after aging. The experimental data will be used for the development of numerical calculation models in B1. The data on materials used and manufacturing processes are available for C2; in addition, the project data will flow into the data management and evaluation concept in C3.

Literature

[SCH1] Wölfel, E., Scheffler, C., Curosu, I., Mechtcherine, V.: Single Fibre Pull-Out Tests of Polypropylene and Glass Fibres in Cement-Based Matrices at High Loading Rates. Proceedings ECCM18 – 18th European Conference on Composite Materials, 24-28 June, 2018, Athens, Greece; pp. 1-8 (published online).

[SCH2] Wölfel, E., Scheffler, C.: Interphases in polypropylene and glass fiber reinforced cementitious model composites under dynamic loading. In Pijaudier-Cabot et al. (eds.) 10th International Conference on Fracture Mechanics of Concrete and Concrete Structures FraMCoS-X, 23-26 June, 2019, Bayonne, France.

[SCH3] Wölfel, E., Brünig, H., Curosu, I., Mechtcherine, V., Scheffler, C.: Dynamic single-fiber pull-out of polypropylene fibers produced with different mechanical and surface properties for concrete reinforcement. Materials, 14(4), 722, 2021

[SCH4] Popa, M. M., Brünig, H., Curosu, I., Mechtcherine, V., Scheffler, C.: Spinability and Characteristics of Particle-Shell PP-bicomponent Fibers for Crack Bridging in Mineral-Bonded Composites. In RILEM-fib International Symposium on Fibre Reinforced Concrete (pp. 255-264). Springer, Cham. 2021

[SCH5] Popa, M. M.; Leuteritz, A.; Stommel, M.; Mechtcherine, V.; Scheffler, C.: Treatments of Polypropylene Bicomponent Fibers to optimize their Interlocking in Concrete by Micro-CaCO3 particle addition. Proceedings ECCM20 – 20th European Conference on Composite Materials, 26-30 June, 2022, Lausanne, Switzerland; accepted

[SCH6] Popa, M. M.; Leuteritz, A.; Stommel, M.; Kühnert, I.; Mechtcherine, V.; Scheffler, C.: Polypropylene Bicomponent Fibers for Improved Mechanical Interlocking for Enhanced Energy Absorption in Strain-Hardening Cement Based Composites. Cement and Concrete Composites. Submitted

Contributors

© Dominik Junger

Doctoral Researcher

Julia Hübner, M.Sc.

- huebner@ipfdd.de

- +49 351 4658 1345

- +49 351 4658 362

in cooperation with

Univ.-Prof. Dr.-Ing. Viktor Mechtcherine

Institute of Construction Materials

Von-Mises-Bau, 3rd Floor, Room 315A Georg-Schumann-Straße 7

01187 Dresden

Germany

- Mechtcherine@tu-dresden.de

- Institute

- +49 351 463 36311

- +49 351 463 37268

in cooperation with

Prof. Dr.-Ing. Christina Scheffler

Institute of Textile Machinery and High

Performance Material Technology (ITM)

Hohe Straße 6, Room 138

01069 Dresden

Germany

- scheffler@ipfdd.de

- Institute

- +49 351 463 39300

- +49 351 463 39301