Projects Overview A3/III Influence of ageing and environmental conditions on the impact resistance of mineral-bonded reinforcing materials with hybrid fibre reinforcement

A3/III Influence of ageing and environmental conditions on the impact resistance of mineral-bonded reinforcing materials with hybrid fibre reinforcement

Motivation

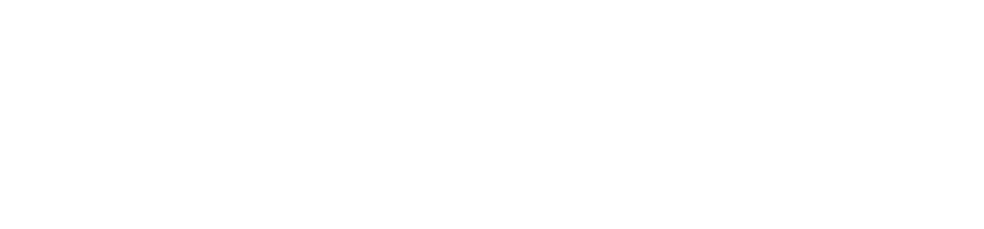

The strengthening layers as developed within GRK 2250 must be able to deliver their protective function against impact loading for many years or rather decades. Thus, any considerable changes in the performance of protecting materials in time need to be known and considered. For quasi-static loading, mechanical performance characteristics of fibre-reinforced mineral-based composites have been found to depend on the material’s ageing and environmental conditions such as moisture, temperature, and chemical composition [1-3]. This is assumed to be due to changes in the proportions among mechanical properties of the composite’s constituents in the first place. No such research is known for impact loading. However, the effects of aging and environment on impact resistance can be expected to be very different in comparison to quasi-static loading, since the loading rate affects the mechanical behaviour of the constituents in various manners so that the proportions shift pronouncedly and not necessarily beneficially [4].

Possible effects of ageing on the mechanical performance of the strengthening material

State of research and own preliminary work

Mechtcherine et al. [5] pointed out a decrease of tensile strength and a concomitant increase of strain capacity for SHCC (Strain-hardening cement-based composites) at elevated temperature, while adverse effect was found with respect to the increasing loading rate. In other preliminary studies at IfB, lower strain capacity was measured for the temperatures below room temperature under quasi-static loading, while a pronounced increase in ductility was recorded with increasing moisture content of the specimens. Liu et al. [6] observed a decrease in fibre/matrix interfacial chemical bond and an increase in interfacial frictional bond upon both sulphate and sulphate-chloride exposures leading to changes in the quasi-static performance. No research is known on the performance of SHCC, TRC or mineral-based composites with hybrid reinforcement under impact loading after accelerated ageing or storing at various moisture conditions.

Scientific problem and project goals

- Investigating the influence of moisture condition and temperature on selected composites developed in Cohorts I and II on their performance under impact loading, including investigations on individual constituents.

- Understanding the changes in the bond between fibres (short and continuous) and the surrounding matrix after accelerated ageing, including carbonation, and subsequent effects on the impact resistance of the composite.

- Assessing the mechanisms leading to changes in the impact resistance of composites with hybrid fibre reinforcement after different storage / exposure conditions.

- Extending micromechanics-based analytical models for describing the strain-rate-dependent tensile behaviour of SHCC and TR-SHCC to encompass ageing, deterioration and moisture conditions.

- Developing strategy for enhancing resilience of the composites against effects of aging and condition changes.

Interaction with other Projects of Cohort III

The long-term assessment of strengthening fibre-reinforced mineral-bonded composite layers pave the way to several joint studies, like e.g., with structural engineering projects A5 and A6, to develop durability-driven design criteria, which are currently not exhaustive, depending on the main risk factors related to environmental exposure (e.g., alkaline, saline, moisture, direct solar exposure), application technology (wet lay-up, shotcrete, 3D printing) and material combination of the strengthening layer (fibre, textile, and matrix constituents). In this regard, close collaborative research is expected with Projects A1 and A2 to determine the best material combinations against specific harsh conditions. Further interaction with the numerical projects (esp. projects B1 and B3) is required. Sustainability analyses and design optimisation strategies (projects C2 and C3) can be refined taking into consideration the long-term performance of strengthening layers applied on representative structural elements (e.g., columns, walls), which affects the resilience properties of composites, including end-of-life circular scenarios.

References

[1] van Zijl, et al.: Durability of strain-hardening cement-based composites (SHCC). Materials and Structures 45 (2012) 1447-1463.

[2] Mechtcherine, V.: Towards a durability framework for structural elements and structures made of or strengthened with high-performance fibre-reinforced composites. Construction and Building Materials 31 (2012) 94-104.

[3] Kabele, P., Novák, L., Nemecek, J., Pekar, J.: Multiscale experimental investigation of deterioration of fiber-cementitious composites in aggressive environment. Proceedings of MHM (2007) 270-271.

[4] Curosu, I., Mechtcherine, V., Forni, D., Cadoni, E.: Performance of various strain-hardening cement-based composites (SHCC) subject to uniaxial impact tensile loading. Cement and Concrete Research 102 (2017) 16-28. DOI: 10.1016/j.cemconres.2017.08.008

[5] Mechtcherine, V., Silva, F., Müller, S., Jun, P., Toledo Filho, R.D.: Coupled strain rate and temperature effects on the tensile behavior of strain-hardening cement-based composites (SHCC) with PVA fibers. Cement and Concrete Research 42 (2012) 1417-1427. DOI: 10.1016/j.cemconres.2012.08.011

[6] Liu, H., Zhang, Q., Li, V., Su, H., Gu, C.: Durability study on engineered cementitious composites (ECC) under sulphate and chloride environment. Construction and Building Materials 133 (2017) 171-181.

Contributors

© Dominik Junger

Doctoral Researcher

AMEER HAMZA AHMED, M.SC.

- ameer_hamza.ahmed@tu-dresden.de

- +49 351 463-42852

- +49 351 463-37268

Principal Investigator

Univ.-Prof. Dr.-Ing. Viktor Mechtcherine

Institute of Construction Materials

Von-Mises-Bau, 3rd Floor, Room 315A Georg-Schumann-Straße 7

01187 Dresden

Germany

- Mechtcherine@tu-dresden.de

- Institute

- +49 351 463 36311

- +49 351 463 37268

in cooperation with

Univ.-Prof. Dr.-Ing. habil. Dipl.-Wirt. Ing. Chokri Cherif

Institute of Textile Machinery and High

Performance Material Technology (ITM)

Hohe Straße 6, Room 138

01069 Dresden

Germany

- chokri.cherif@tu-dresden.de

- Institute

- +49 351 463 39300

- +49 351 463 39301

in cooperation with

Prof. Dr.-Ing. Christina Scheffler

Institute of Textile Machinery and High

Performance Material Technology (ITM)

Hohe Straße 6, Room 138

01069 Dresden

Germany

- scheffler@ipfdd.de

- Institute

- +49 351 463 39300

- +49 351 463 39301

in cooperation with

Prof. Dr. Edeltraud Günther

Institute of Construction Materials

Von-Mises-Bau (VMB), Room 101A Georg-Schumann-Straße 7

01187 Dresden

Germany

- edeltraud.guenther@tu-dresden.de

- Institute

- +49 351 463 34313

- +49 351 463 37764