Projects Overview B1/III Multi-scale simulation of dynamic fibre pull-out and crack propagation in mineral-bonded composites under impact loading

B1/III Multi-scale simulation of dynamic fibre pull-out and crack propagation in mineral-bonded composites under impact loading

Motivation

For the resistance of SHCC (Strain-hardening cement-based composites) under impact loading, the dynamic fibre pull-out behaviour on the microscale in combination with crack propagation properties of the heterogeneous matrix material are crucial. In order to simulate and predict this behaviour, computational methods for the simulation of dynamic fibre pull-out and crack propagation need to be combined and embedded in a multiscale method suitable for the simulation of localisation effects.

State of research and own preliminary work

The combination of the variant of the multi-scale projection method [Lö1-Lö3] developed further in the second cohort and the newly developed extended phase-field method (XPFM) [Lö4] allows for the efficient simulation of dynamic crack propagation in macroscopic components with heterogeneities on the mesoscale. Mesostructures with micro-heterogeneities can also be simulated. For the simulation of the complex fibre pull-out behaviour in SHCC, however, cohesive zone elements are suitable, since the location of the delamination is known in the fibre pull-out. Classical cohesive zone elements are based on a traction-separation-law and therefore cannot take into account the membrane stresses occurring in the cohesive zone.

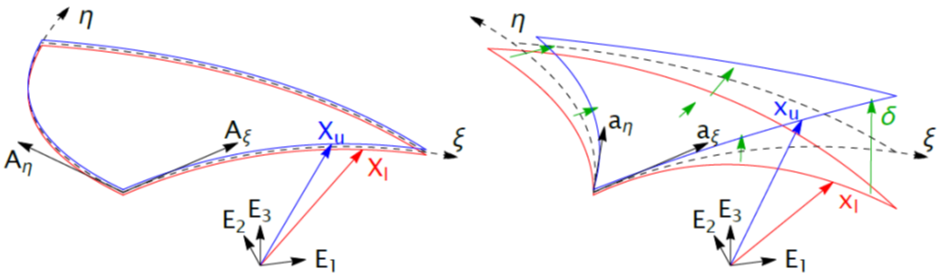

Kinematics of the Membrane-Mode-Enhanced-Cohesive-Zone-Element. Undeformed (left) and deformed (right) state

In recent years, several cohesive zone elements have been developed in the applicant’s working group that can take membrane stresses into account and can be adapted for the simulation of fibre pull-out tests [Lö5, Lö6]. In particular, the membrane-mode-enhanced-cohesive-zone-element (MMECZE) [Lö6] is a promising approach for the application in fibre pull-out simulations.

Scientific problem and project goals

The project will investigate the combination of the XPFM for the simulation of crack propagation in the matrix material with the MMECZE formulation for modelling the delamination behaviour between matrix and fibre in order to reflect the complex interaction of these two failure mechanisms. This interaction is crucial for determining the local resilience of SHCC. In order to be able to capture the localisation effects that occur during failure on the microscale under realistic boundary conditions on the next coarser scale, it is planned to embed the simulation methodology in the multi-scale method for dynamic crack propagation developed in the second cohort.

Interaction with other projects of Cohort III

A close cooperation is planned with subproject A2/III to setup and validate the material modelling of the membrane-mode-enhanced-cohesive zone element. A cooperation with A3/III is also intended for the calibration and validation of the model to be developed. Further cooperation is planned with the numerically oriented projects B3/III and B4/III for material and multiscale modelling. The method can be used for the numerical simulation of small material sections of all demonstrators.

Literature

[Lö1] Loehnert, S.; Belytschko, T.: A multiscale projection method for macro/microcrack simulations. International Journal for Numerical Methods in Engineering 71 (2007), 1466 – 1482.

[Lö2] Holl, M.; Loehnert, S.; Wriggers, P.: An adaptive multiscale method for crack propagation and crack coalescence. International Journal for Numerical Methods in Engineering 93 (2013), 23 – 51.

[Lö3] Holl, M.; Rogge, T.; Loehnert, S.; Wriggers, P.; Rolfes, R.: 3D multiscale crack propagation using the XFEM applied to a gas turbine blade. Computational Mechanics 53 (2014), 173 – 188.

[Lö4] Loehnert, S.; Krüger, C.; Klempt, V.; Munk, L.: An enriched phase-field method for the efficient simulation of fracture processes. Computational Mechanics (submitted)

[Lö5] Töller, F.; Loehnert, S.; Wriggers, P.: Bulk material models in cohesive zone elements for simulation of joining zones. Finite Elements in Analysis and Design 164 (2019), 42 – 54.

[Lö6] Töller, F.; Loehnert, S.; Wriggers, P.: Membrane mode enhanced cohesive zone element. Engineering Computations 39 (2022), 722 – 743.

Contributors

© Dominik Junger

Doctoral Researcher

MAJD TABIB, M.SC.

Institute of Mechanics and Shell Structures

Technische Universität Dresden,

ABS, Room 03-015

August-Bebel-Straße 30/30A

01219 Dresden

Germany

- majd_mahmoud_othman.tabib@tu-dresden.de

- +49 351 463 36658

- +49 351 463 43235

Principal Investigator

Prof. Dr.-Ing. Stefan Löhnert

Institute of Mechanics and Shell Structures

TU Dresden, Faculty of Civil Engineering, 3rd floor, room 03-017

August-Bebel-Straße 30

01219 Dresden

Germany

- stefan.loehnert@tu-dresden.de

- Institute

- +49 351 463 43231

- +49 351 463 43235

in cooperation with

Prof. Dr.-Ing. Christina Scheffler

Institute of Textile Machinery and High

Performance Material Technology (ITM)

Hohe Straße 6, Room 138

01069 Dresden

Germany

- scheffler@ipfdd.de

- Institute

- +49 351 463 39300

- +49 351 463 39301